Dron & Dickson were recently contracted to deliver Electrical & Instrumentation (E&I) services for a major project. The scope involved installing a new High Voltage (HV) transformer room and upgrading an existing Low Voltage (LV) switchroom. Key requirements included ensuring minimal disruption to ongoing plant operations and strictly adhering to the client’s Local Standard Operating Procedure (LSOP) and permit-to-work procedures.

-

-

Dron & Dickson’s project team prepared detailed work packs before mobilising an experienced onshore team to the site. The team coordinated closely with the client’s maintenance crew to manage planned outages, ensuring alignment with essential maintenance needs.

Key project tasks included:

• Demolition: Removal of existing plant infrastructure, including dismantling of heavy machinery and over 2,500 meters of SWA/MCC cabling (ranging up to 240mm).

• Bill of Materials (BOM) and Procurement: The project team produced a comprehensive BOM, and our Wholesale team collaborated with manufacturers to secure materials, offering the best value.

• Cable Management System: Installation of heavy-duty cable tray, trunking, and ladders from internal areas to an external high-level gantry.

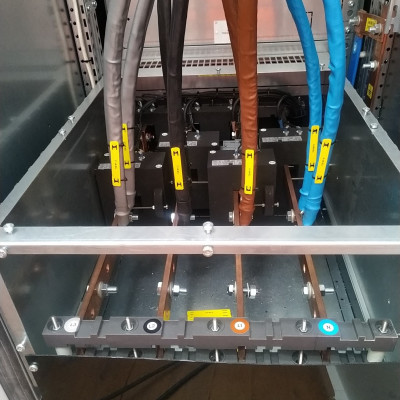

• HV/LV Cable Installation: This involved cable pulling, glanding, and termination of both HV and LV cables.

• Commissioning and Inspections: Final commissioning was performed, including tagging and Ex inspections of both the newly installed and existing equipment to ensure compliance with safety and operational standards. -

The project was successfully completed, resulting in the seamless handover of fully compliant assets. The upgraded switchroom delivered improvements in energy efficiency, reduced maintenance costs, and future-proofed the network for years to come. Importantly, the work was completed incident-free, aligning with Dron & Dickson’s core value: “Everyone Home Safe.”

-

Gallery

Terminations

Low voltage switch gear

High voltage (11kv) transformers

-

Download PDF