A North Sea operator experienced multiple functional issues including oil contamination and sticking pneumatic components within aspirator gas detector panels on one of their offshore assets. The operator carried out a site survey which interrogated each of the 33 panels individually. The survey report was sent to Dron & Dickson who engaged with the operator and collaborated to provide a solution and provide a remedial solution.

-

-

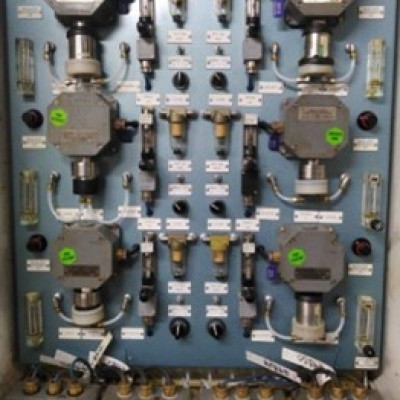

Two experienced back-to-back teams of competent Dron & Dickson Technicians were deployed offshore for a 5-month duration to conduct the work scope. Ongoing onshore support was provided by a Dron & Dickson Project Coordinator and a Technical Authority. All 33 aspirator gas detector panels and associated flow switches were disconnected and removed individually and prepared for bench testing and overhaul in the asset’s maintenance workshops. All instrumentation, equipment and components were removed, disassembled, cleaned and checked for serviceability as per manufacturers specifications. Panel components were then renewed or refitted and everything was function and leak tested in the site workshop.

New upstream anti condensate filtration pots were fitted along with new small bore tubing assemblies. Panels were then reassembled, installed, and tested again in situ prior to being recommissioned back into service.

Panels were a mixture of:

• 2 Way Panels

• 3 Way Panels

• 5 Way Panels

• 6 Way Panels

Equipment maintained included:

• Flow switches

• Test switches

• Eductors

• Flow meters

• Gas detectors

• Filtration pots & elements

• Ex junction boxes

• Tubing & fittings

• Sampling valves

• Flow/pressure regulators

• Automatic drains -

All the overhauled aspirator gas detector panels are once again fully functional and include upstream anti condensate filtration. The operator has a stock profile of critical spare parts to ensure future operations are maintained, and exposure to contamination is mitigated.

Post-handover, our client has indicated that savings are over 35% compared to their previous approach. In addition, all repair costs are known upfront, savings identified, full traceability and auditability and a plan for ongoing improvement are included. All items tested in accordance with HSE Guidance HSG17 and inspected to comply with BS EN 60079 Part 17. -

Gallery

Overhauled Aspirated Panel

Overhauled Instrumentation

Upstream Small Bore Tubing

-

Download PDF